Current Sensing Circuit: Benefits and Applications

July 14, 2011PLC Programming: Perplexed by Programming PID Loops in Your PLC?

July 16, 2011

Linear Actuator Controller for Edge Guiding

Carotron’s Edge Guider – Click Here!

| Edge guiding is the most common method used to control web position and achieve an accurate edge alignment for film, while in its various stages during the production process. A linear actuator controller is used in edge guiding to ensure this process stays on course.

Why is edge guide control so important? This is extremely important in an industrial setting or any application where web film or material needs to be manipulated with preciseness. Process lines rely emphatically on actuator control systems to ensure that the strip position is maintained throughout the process. Whether needed for a simple edge guiding process or a complex operation for slitting, these control systems can produce high quality product while keeping operation expenses to a minimum.

|

The Process in Edge Guiding Control

The linear actuator controller is used to calculate the difference for the given position. Once this has been determined, it controls the actuator proportionately. The actuator in turn guides the film/web material back to the reference position. Once in place, the web material can be controlled and processed accurately, while in its lateral position. A sensor is used to detect positioning continuously for the web edge or line.

There are basically three main components in web edge guiding: the sensor, the actuator and the controller. There are many types of linear actuator controllers based on the type of web material, application and equipment speed. The response gain enhances as the web speed increases, thus giving continuous proportionate correction to the actuator. Controller types include analog, digital and pneumo hydraulic.

There are also various types of sensors and actuators, depending on the type of application, material and environment. Some common sensor types include pneumatic, infra red, line/edge, CCD, opto electronic and ultrasonic. Actuators may be hydraulic or electro mechanical. The frame types include rewind, unwind, TRA, SRA and motorized sensor positioner. Some manufacturers offer custom actuator or controller design if you have special edge guiding or control requirements.

Common Applications

Linear actuator controllers can help in guiding the thinnest plastic film or the thickest metal strip, or very narrow or wide webs. These can benefit in a wide variety of applications, including slitting machines, flexo and gravure printing, extrusion laminate, blown film, extruders and others.

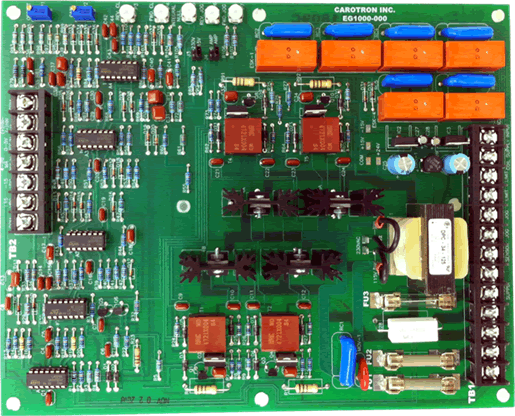

One example is the Edge Guider EG1000-000 by Carotron, Inc. It is a linear actuator controller that can handle 90 VDC armature P.M. motors up to 1/2 HP as well as 180 VDC P.M. motors up to 1 HP. You can view the manual, specs, diagrams for connections and dimensions, and more at the main product page. Or call to speak with a qualified engineer to discover the best actuator control solution for your edge guiding application.

One example is the Edge Guider EG1000-000 by Carotron, Inc. It is a linear actuator controller that can handle 90 VDC armature P.M. motors up to 1/2 HP as well as 180 VDC P.M. motors up to 1 HP. You can view the manual, specs, diagrams for connections and dimensions, and more at the main product page. Or call to speak with a qualified engineer to discover the best actuator control solution for your edge guiding application.

Resource/Copyright Info: This motor control article about linear actuator controllers for edge guiding is under © Copyright of Carotron, Inc., your source for high quality DC and AC motor drives and other industrial motion control products to keep your operation running smoothly.