- Have any questions?

- +1 803.286.8614

- saleserv@carotron.com

Control Systems Application Guide

|

Previous “Center Driven Winders and Unwinders” • Back To Index • Next ““Non-contact” Loop Control”

A “tension controlled zone” can exist between any two adjacent and controlled rolls in a web transporting system.

“Controlled” means having motoring or braking force regulated by a brake, clutch or drive and motor. The web must be positively gripped by these rolls so that the applied force is completely and evenly imparted as desired tension.

All of the Multiple Drive systems and Center Drive control systems we’ve already discussed meet these criteria. Those velocity controlled drive systems with no active tension controlling or feedback device such as a dancer or load cell must rely on web compliance and operator attention to Speed Trimming for acceptable operation.

The various Torque control methods provide “open loop” tension control by virtue of internal signal processing within the drives. The addition of “special function devices for diameter sensing or smart circuits for calculating diameter and other required torque signals for complete CTCW control gives respectable performance in many applications – without the addition of active feedback devices.

Then, velocity mode center driven winder and unwinders with active feedback from dancers and load cells use sophisticated signal processing to compensate for diameter change and transient operating conditions such as speed change, load change and tension command change.

In some cases an isolated zone of lower or higher than normal tension must be established for special web processing such as drying with overfeed, coating, sizing, slitting, punching, etc. With the exception of diameter compensation when not applicable, all of the described control methods can be used for Zone Tension control for surface driving and/or braking rolls.

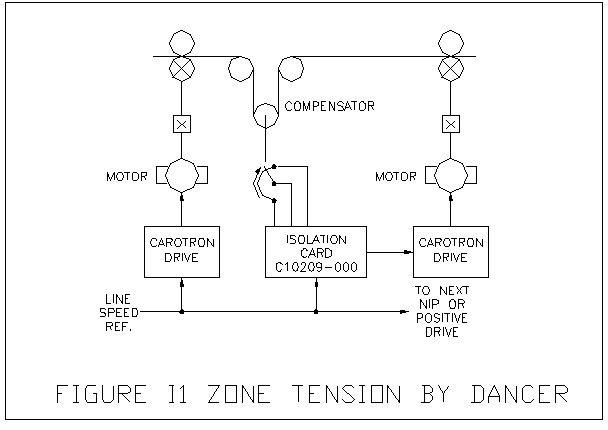

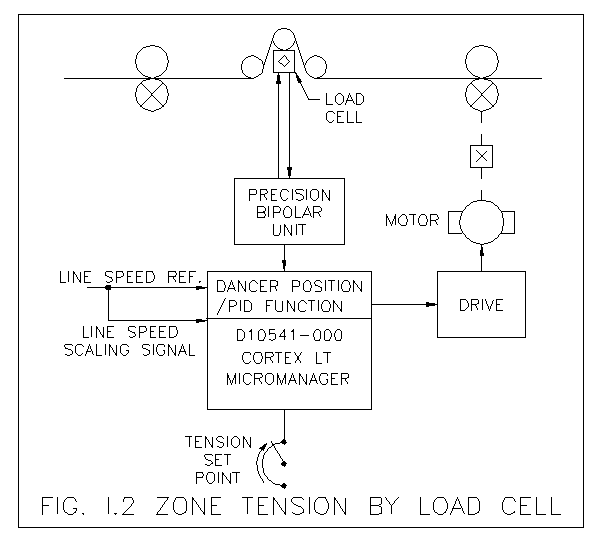

Some examples are shown in Figures I.1 and I.2.

Figure I.1 illustrates “closed loop” zone tension control with dancer feedback. As in all dancer feedback systems, the tension is controlled by the force exerted by the dancer or compensator arm. Since the dancer pot here is used as a trimming device, transient errors in tension may cause a shift in dancer position until a balancing speed correction is produced.

Figure I.2 shows zone tension control using load cell feedback. Here the “exit” drive follows the “entry” speed with greater tension accuracy maintained through the use of a PID function circuit providing a + percentage speed correction.

In both of these examples, proper gearing of the exit roll is important. It must be geared to “greater than line speed” to give “catch-up” capability when operating at maximum line speed. Again, in both examples, the range of the tension correcting dancer or load cell circuit should be minimized to only that level required for proper control.

APPLICABLE PRODUCTS

CLT2000-000 CORTEX LT CONTROLLER

D10541-000 DANCER POSITION (PID) CONTROL

C10032-000 SIGNAL FOLLOWER CARD

D10562-000 PRECISION BIPOLAR ISOLATION CARD

SIM200-000 SIGNAL ISOLATION MODULE

Previous “Center Driven Winders and Unwinders” • Back To Index • Next ““Non-contact” Loop Control”

Go to Product Line • Go to DC Drives and Accessories • Go to System Interface Components

Vous cherchez des sources fiables pour acheter steroide sur Internet ? Pourbien choisir, voici le steroide fr avis des utilisateurs sur les meilleurs shops.

Discover the world of gambling at houseofpokies. Also explore the exciting slots at HouseofPokies

Welcome to https://casino-winorama.com/ in 2023! Experience thrilling games and big wins. Ready to rocket your luck?

Dive into the thrill at Apollo Slots Casino! Start your adventure with an easy Apollo Slots mobile login from anywhere in South Africa!