- Have any questions?

- +1 803.286.8614

- saleserv@carotron.com

Control Systems Application Guide

|

Previous “Winder Traverse Drive “ • Back To Index • Next “Proportional Edge Guiding”

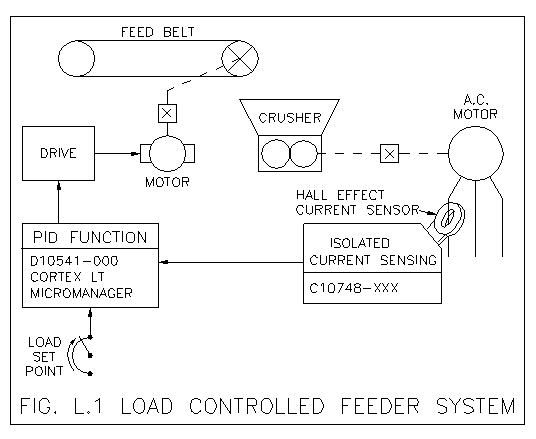

This application guide discusses load regulated feeder control. Feed belts and conveyors which deliver product to crushers, grinders, shredders and similar processes are excellent candidates for load regulation of the feed rate to prevent “choking” or overloading of the process. The crusher device is typically driven by an AC induction motor. The load current of this motor will change in proportion to the volume of material delivered. In order to maintain the optimum crushing consistency and prevent jam-ups or overloads, the feed rate must be controlled based on the loading of the motor.

The Carotron Current Sensing Card can be used to monitor the AC motor current and convert it to a proportional voltage level. This voltage now becomes the feedback input to a PID function circuit with the setpoint becoming the desired operating load level. This arrangement will control the speed of the feeder motor to match the crusher load feedback from Current Sensing Card to the load setpoint. Another feature of this motor control method allows the top speed of the feeder to be limited during periods of light or no material flow.

APPLICABLE PRODUCTS

C10748-000 CURRENT SENSING BOARD

CLT2000-000 CORTEX LT CONTROLLER

D10541-000 DANCER POSITION (PID) CONTROL

Previous “Winder Traverse Drive “ • Back To Index • Next “Proportional Edge Guiding”

Go to Product Line • Go to DC Drives and Accessories • Go to System Interface Components

Vous cherchez des sources fiables pour acheter steroide sur Internet ? Pourbien choisir, voici le steroide fr avis des utilisateurs sur les meilleurs shops.

Discover the world of gambling at houseofpokies. Also explore the exciting slots at HouseofPokies

Welcome to https://casino-winorama.com/ in 2023! Experience thrilling games and big wins. Ready to rocket your luck?

Dive into the thrill at Apollo Slots Casino! Start your adventure with an easy Apollo Slots mobile login from anywhere in South Africa!